Description

Slickline Gauge Cutter

Technical Description and Specifications

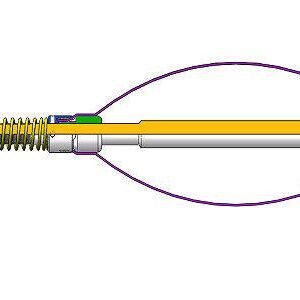

The Slickline Gauge Cutter is a fundamental diagnostic and preparation tool, often referred to as the “scout” of the tool string. It is typically the first tool run into the wellbore to verify that the tubing is clear of obstructions—such as scale, paraffin, or salt—and to ensure that the internal diameter (ID) of the tubing is sufficient for the subsequent deployment of larger or more complex Bottom Hole Assemblies (BHA).

Key Technical Specifications and Operation

Function: Its primary role is to “drift” the tubing. By running a gauge cutter slightly smaller than the tubing drift ID, the operator can confirm a clear path for plugs, packers, or gauges. It also acts as a scraping tool to remove minor debris from the tubing walls.

Design & Fluid Bypass: The tool features a hollow, cylindrical body with large Bypass Ports. these holes allow well fluids to pass through the tool as it is lowered or raised, preventing a “piston effect” (swabbing) that could cause a surge in well pressure or accidental tool string lift.

Cutting Edge: The bottom of the tool is machined into a sharp, hardened circular edge. This edge is designed to shear through soft obstructions or scale. In some aggressive environments, the edge is heat-treated or hard-faced with specialized alloys to maintain sharpness.

Standard Sizing: The Outside Diameter (OD) is the most critical dimension. It is typically selected to be 0.010″ to 0.030″ smaller than the minimum ID of the tubing or the “drift” of the completion.

Fish Neck: Like all standard slickline tools, it features an integral Industry Standard Fish Neck on the top, allowing for easy retrieval by a pulling tool if the wire breaks or the tool becomes stuck.

Customization and Materials

Material: Manufactured from high-tensile Carbon Steel or 4140 Alloy Steel for standard operations. For corrosive environments, it is available in 17-4 PH Stainless Steel or other corrosion-resistant alloys.

Hard-Facing: For heavy scale or sand-laden wells, the cutting edge can be “dressed” with tungsten carbide or similar hard-facing materials to extend tool life.

Thread Connections: Standard slickline connections (e.g., 15/16″-10 UN or 1-1/16″-10 UN) to match the rest of the BHA.

Critical Parameters

| Parameter | Customizable Range |

| Tool OD (Outside Diameter) | 1.00″ up to 6.00″ (Wellbore Dependent) |

| Bore/Bypass Size | Optimized for fluid flow vs. tool strength |

| Connection Size | 15/16″, 1-1/16″, 1-1/2″ Pin/Box |

| Service Rating | Standard or Sour Service |

| Hardness (Edge) | 45-55 HRC (Typical for hardened steel) |

Reviews

There are no reviews yet.